How NOT to fit a Deadlock

How NOT to fit a Deadlock

We recently had a customer pop in to ask us to rectify a lock that had been fitted very poorly by another company. The customer had paid the company to fit a Deadlock to his van, but the engineer obviously didn’t know what he was doing and the install went very wrong!

Where did it go wrong?

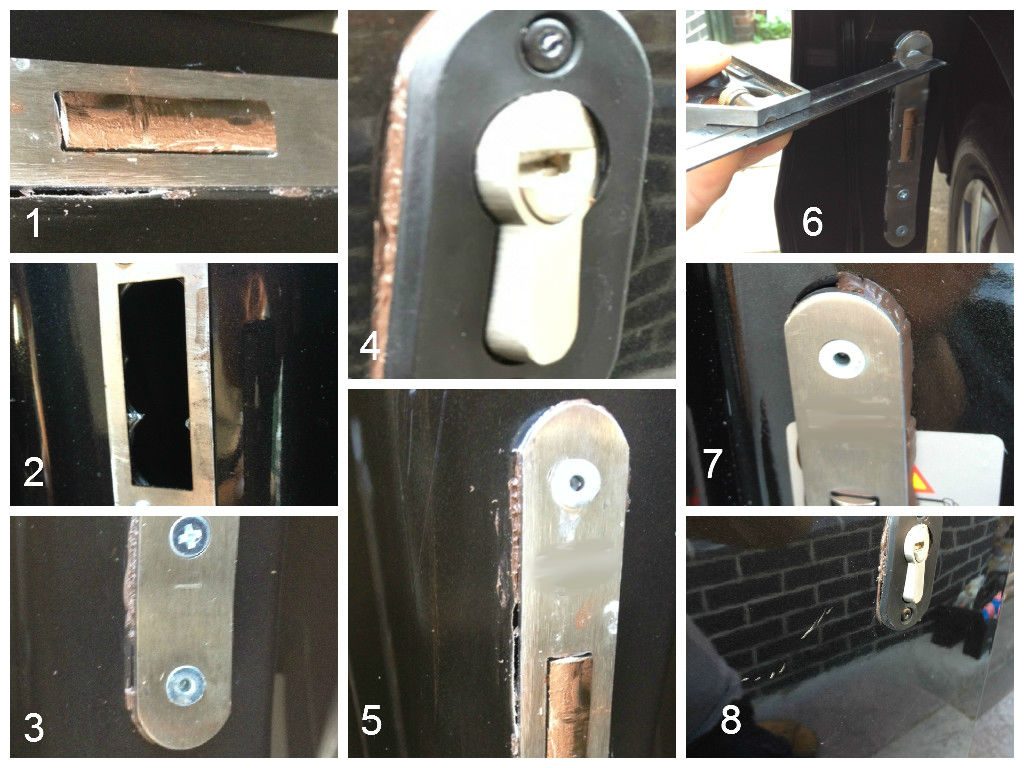

This is how the lock looked after the install (please note we were NOT the company to fit this lock):

Image 1) The hole for this lock has been cut far too big and therefore there are gaps around the lock.

Image 2) The installer was too lazy to even clean the hole (by filing it down) before fitting the lock. This is a simple process that helps to make the lock watertight (wax oil or paint should also be used to prevent rusting).

Image 3) The silicone use by this engineer was brown and did not match the vehicle colour. This makes the lock look unprofessional. The silicone was also added AFTER the lock was fitted but it should have been put on the lock before fitting to ensure a watertight and secure installation.

Image 4) The key barrel, as seen in the picture, is at the wrong angle because the internal lock mechanism was fitted too far away (see image 6). You can also see the brown silicone around the lock, which shouldn’t be the case.

Image 5) The edges of the lock are sharp and there are gaps around the lock meaning it is not watertight. You can also see in this image that the hole underneath has been cut too big and filled with brown silicone to try and hide this.

Image 6) The lock has been fitted too far away. In this image, you can see the lock has been fitted in the incorrect place. The engineer obviously did not measure correctly.

Image 7) The silicone is not only the wrong colour but has been put on after the lock and has not even been put on around the whole lock (as seen in this image). This means the lock is not watertight and will rust.

Image 8) The engineer that fitted this lock also managed to damage the van. You can see some scratches in this image where the engineer was not careful. In the rear door, there are also dents in the door. The dents were likely to be caused by the fact the engineer did not drill a “pilot hole”, but instead used a drill that was too big, thus causing the metal of the door to dent.

What is a Deadlock and how does it work?

If a Deadlock is fitted correctly it can be of great value in helping to prevent a vehicle from getting broken into – it would take a fully qualified engineer roughly 1 hour to fit a Deadlock. If the lock is fitted incorrectly it can be very unsightly and can cause a lot of damage to a vehicle, as was the case for this customer.

How can this be rectified?

One of our expert engineers attended site to see how this Deadlock could be rectified. The conclusion he came to is that the rear door will need to be replaced and made watertight. The dent will also need to be repaired by an expert. The main concern he has was that the side door showed really poor workmanship, and therefore he recommended taking the lockout completely and restarting. It is likely a plate would have to be fitted behind the lock; as the hole that has been cut to fit the lock is much too large.

The Deadlock in the image below has been fitted correctly by a Vehicle Accessories Ltd engineer. The lock has been made watertight with wax oil (thus it won’t rust) and the lock is aesthetically pleasing. The mechanism also works perfectly on this lock as the engineer measured everything before fitting to ensure a perfect fit.

When purchasing such security systems for your vehicle, make sure you know who is fitting the product. More importantly, make sure the engineer is experienced and qualified. At Vehicle Accessories Ltd all of our engineers have undergone expert training and have years of experience. We can supply and fit locks for vans Nationwide. Find out more by visiting yg0jcb.vehicle-accessories.net/lock-security .